The airport is a place of joy and adventure, but also a place of excitement and hustle and bustle. A lot happens here in a short time. In particular, the processing of passengers and baggage must be fast and effective. One of the most important technologies that help speed up this process is belt conveyors.

Belt conveyors are used at various points in the airport to facilitate the transport of luggage and other items. For example, they are used for bag drops, at check-in counters, and in baggage claim areas. That’s why the use of belt conveyors at the airport is essential to ensure the smooth operation of the airport. However, in order for an airport to operate effectively and efficiently and provide a positive experience for travelers, there are a number of factors that must be taken into account when planning and installing belt conveyors.

Safety first

First of all, the necessary safety must be provided to prevent accidents. Passengers and employees must be able to move safely around the airport. Belt conveyors for transporting luggage and other items can pose a safety risk if not installed or maintained properly. Sources of danger are, for example, the pinching of objects or body parts, slipping or tripping on wet or smooth surfaces, or damaging of luggage or other objects that are transported on the belt conveyor. Belt conveyors should therefore be designed to facilitate the handling of luggage and other items without damaging them or causing system interference. In addition, regular inspections and maintenance are mandatory to ensure the safety of belt conveyors.

Reliable quality is a must

Another important factor for trouble-free use of belt conveyors at the airport is high quality. It ensures that the belt conveyors operate reliably. Smooth operation is important for the whole system: Any failure of a belt conveyor can lead to significant delays in handling passengers and luggage. This in turn can result in a poor customer experience and higher operating costs.

Low overall height is a special challenge

The height of the belt conveyors is also particularly important – for a simple reason: Lower-lying belt conveyors provide passengers with relief and comfort; at bag drops, check-in, and at the baggage claim, because they mean that the luggage doesn’t have to be lifted as high.

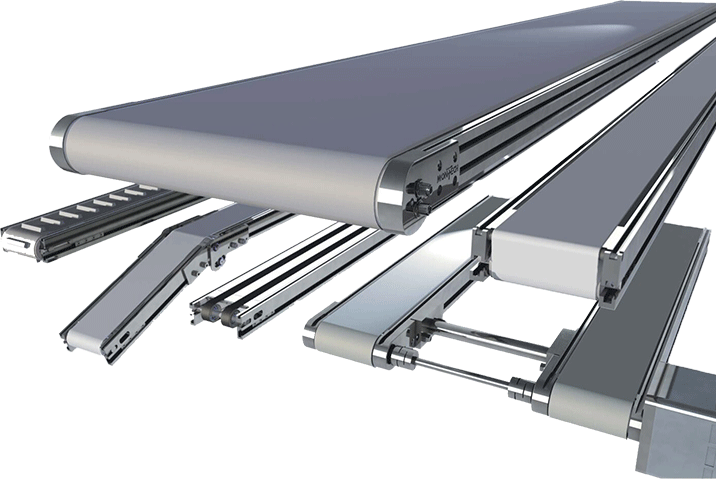

Montech has recognized this need and, with the TB40 belt conveyor, offers an option that distinguishes itself significantly from other belt conveyors on the market. Its low overall height, compact design without lateral contours that get in the way, and the strong 24 V motor that can convey loads of up to 200 kg make the TB40 belt conveyor the perfect choice at the airport. Because the drive is covered by the low-voltage directives, system builders don’t have to worry about contact protection. This is also a major advantage, as it makes it easy to comply with the various country-specific regulations for issuing the system certificate and declaration of conformity.

Conclusion: The TB40 belt conveyor is the right choice

In summary: If belt conveyors fulfill the criteria for safety, reliability, and design, nothing stands in the way of efficient airport operations. The TB40 belt conveyor from Montech is definitely a good candidate; it meets all the required requirements.

Stefanie Lanz | Communication

As a creative spirit, I'm constantly on the lookout for inspiration. I find it while drinking a cappuccino, wandering through city centers or in the laughter of my children.