Employees’ safety is paramount in production facilities. The focus is on avoiding accidents and minimizing potential risks. A proven method of ensuring security in production environments is to provide machine guarding. As special barriers, they play a crucial role in protecting machines and equipment.

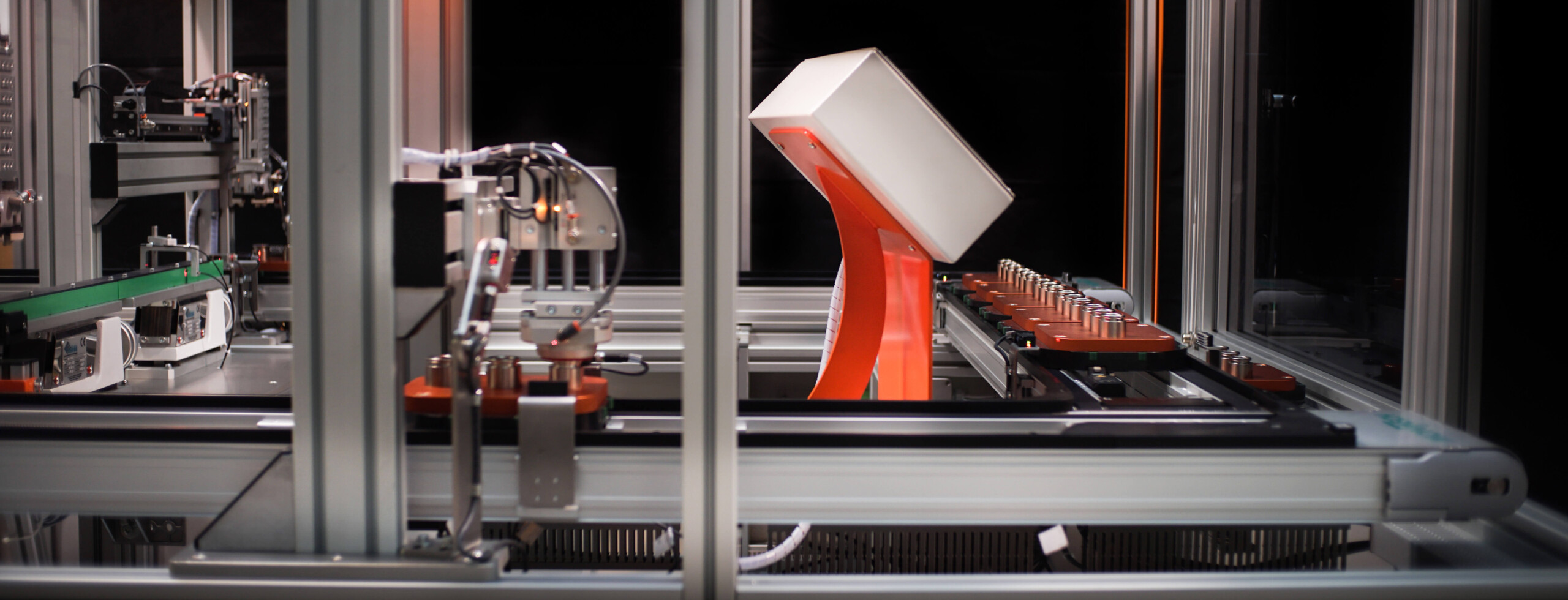

Machine guarding systems are used to restrict access to hazardous machinery and equipment in production environments. They provide physical protection against potential dangers including rotating parts, sharp edges, electrical components, and chemicals. By using protective enclosures, it is possible to avoid accidents, injuries, and damage. They create a clear separation between human and machine and minimize the risk of direct contact or unintentional intervention. Thus, protective enclosures contribute significantly to improving occupational safety and health protection in production operations.

Types of machine guarding systems

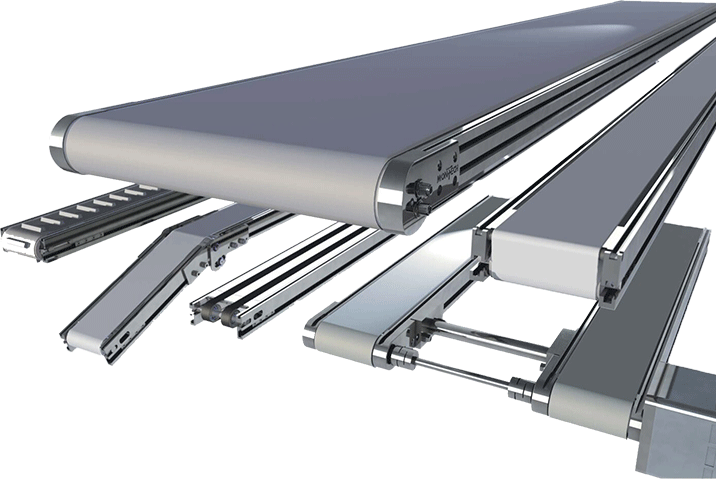

There are two basic types of machine guarding systems: Separating and non-separating machine guarding. Separating machine guarding are physical barriers used to separate people from danger zones or potentially harmful machinery and equipment. They enclose the area completely and prevent access to potentially hazardous components. Such enclosures may include grid fences, protective doors, and locks. Non-separating machine guarding, by contrast, allow access to the protected areas, but still provide a barrier between users and sources of danger. They are designed to ensure a safe working environment by detecting dangers early and taking appropriate safety measures without blocking full access to the machine or equipment. Light grids, safety laser scanners, and safety sensors are examples of non-separating protective enclosures.

Benefits of machine guarding

The use of machine guarding in production plants offers numerous benefits:

- Occupational safety: The main function of protective enclosures is to protect employees from injury. By preventing access to danger zones, they minimize the risk of accidents and create a safe working environment.

- Legal compliance:Machine guarding systems are often required by law to meet occupational safety and health standards. By installing and properly using protective enclosures, companies can ensure that they comply with legal requirements and avoid potential legal consequences.

- Protection against property damage: Machine guarding systems not only contribute to the safety of employees, they also protect the machines and equipment themselves from damage caused by unintentional contact or external influences.

- Increased efficiency: By minimizing potential accident risks, protective enclosures can increase productivity. Employees can focus on their tasks without being distracted constantly by safety concerns.

It’s worthwhile to rely on quality

When choosing the right machine guarding for production operations, it’s important to pay attention to quality. Only high-quality protective enclosures provide the desired protection and have a long service life. It is therefore worthwhile, both financially and in terms of safety, to check the robustness and longevity of protective enclosures when purchasing them. A user-friendly design of the protective enclosure is also recommended for an efficient production day-to-day.

We will be happy to help you select the right machine guarding. Whether safety walls or safety hoods, we offer a wide range of protective enclosures for every need, made of the highest quality materials, and in various sizes.